Wood-fired deck oven

PELLADOR Zyklotherm

and plenty of tradition

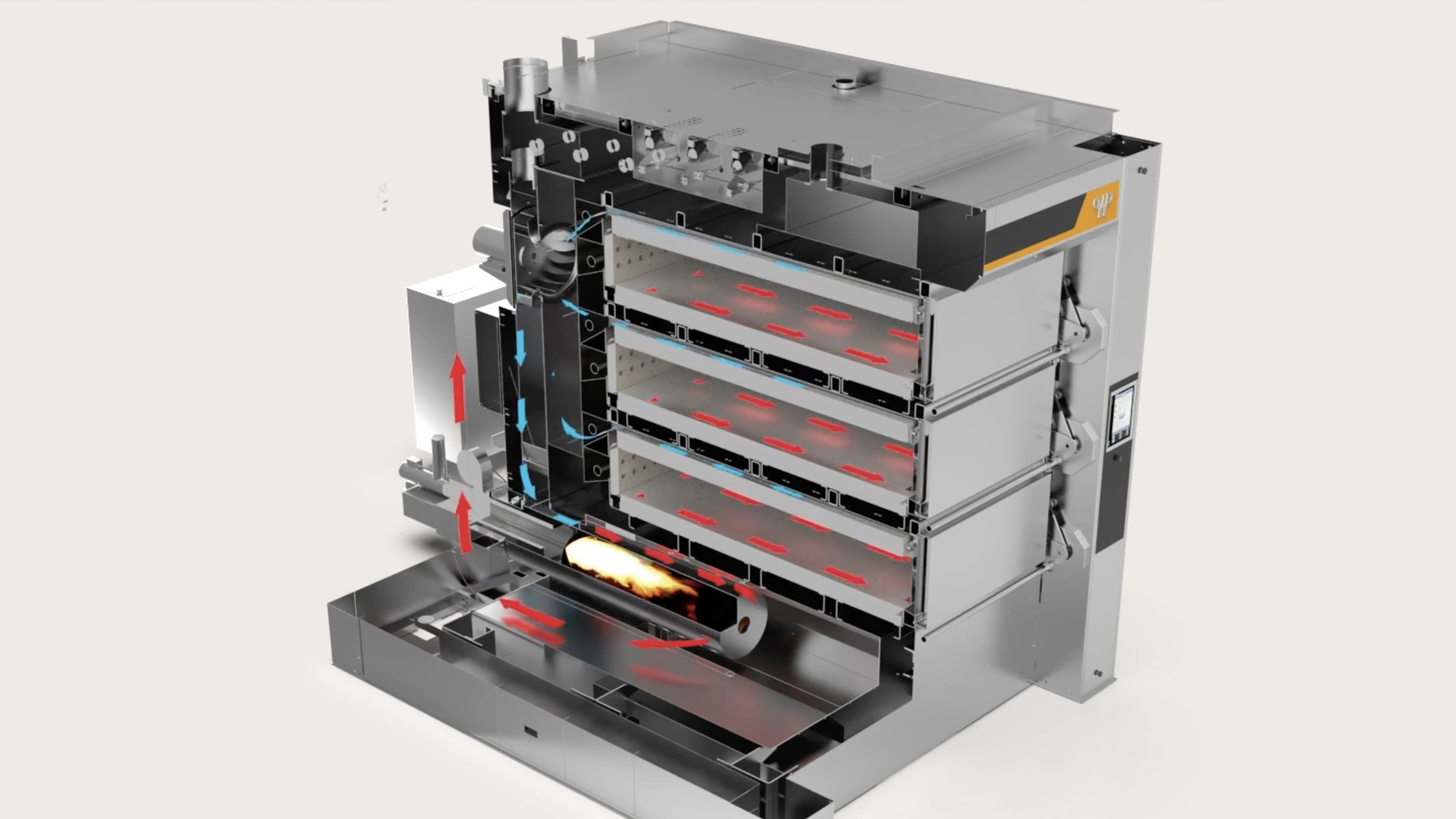

WP deploys the Zyklotherm® principle, already established in the successful MATADOR® deck ovens, in the new PELLADOR Zyklotherm® to further boost efficiency and productivity. The PELLADOR Zyklotherm® is an oven centrally fired with wood pellets, distributing the exhaust gases from wood combustion through channels to the individual decks. This gives the baked goods the typical wood oven flavor, optimizes the utilization of heat energy, and reduces pellet consumption. Ash no longer accumulates in the ovens thanks to the use of a central burner. The baked goods can be marketed as wood-fired oven bread or bread rolls.

Baking trendy wood-fired oven bread economically

Wood-fired oven bread is the trend, as many consumers value artisan food. They greatly value the crispy, flavorful crust, the juicy crumb, the special aroma and the extended freshness that traditional wood-fired baking provides, and they are prepared to pay a higher price for it.

Baking in a wood-fired oven is a cultural tradition that goes back thousands of years. It is based on the principle of heating a baking chamber with wood, and making use of the stored heat to bake bread after the wood has burned down and the ash has been removed. Classic wood-fired baking ovens, however, show low productivity and the baking result is not always consistent. WP Bakery Technologies has revolutionized wood-fired baking with the development of the PELLADOR.

PELLADOR ovens are fired with pellets instead of wood logs. They render baking process exactly the way bakeries demand efficient production: dependable, energy-saving, fast, and sustainable. The quality of traditionally crafted products appeals to the most demanding consumers.

Wood-fired deck oven variants

PELLADOR Zyklotherm

Direct pellet fired + Zyklotherm system

baking area: on request

loading: automatable

The Zyklotherm® technology

This is how to increase productivity!

WP deploys the “Zyklotherm®” technology, already established in the successful MATADOR deck ovens, in its wood-fired baking ovens too, to further significantly boost efficiency and productivity.

Baking with Zyklotherm®

- Switch on the burner.

- Heat up the oven to loading temperature.

- Switch off the burner or close the inlet and outlet valves when the desired temperature has been reached.

- Load and bake the products at decreasing temperature.

- Unload the baked goods, and heat up to loading temperature again for the next baking cycle. Switch on the burner or open the inlet and outlet valves.

- Repeat steps 2 to 4 of the baking cycle.

Advantages of the PELLADOR Zyklotherm wood-fired baking oven

Increased efficiency through central burner

One single pellet burner for the entire oven

In the PELLADOR Zyklotherm®, a single, centrally arranged pellet burner generates the energy required for heating the baking chambers. Channels distribute the exhaust gases and feed them to the decks. The gases enter the baking chambers without a flame. After heating the stone slabs, the gases are not discharged into the flue but instead fed back to the central combustion chamber. Here they are mixed with fresh exhaust gas and fed back into the heating cycle, thus optimizing the efficiency of heat energy and lowering pellet consumption. Ash no longer accumulates in the ovens thanks to the use of the central burner, and the cleaning effort is significantly reduced.

Individually controllable deck ovens

Each baking chamber can be separately controlled. As soon as the desired baking temperature has been reached, the inlet and outlet valves are closed to interrupt the supply of exhaust gas, and the baking process can start.

Continuous combustion

Thanks to the controllable exhaust gas supply via channels and valves, there is no longer any need to interrupt the combustion process. The time-consuming start-up phase and the burn-off phase after the pellet supply has ended are eliminated. In addition, heating the ceiling slabs from both sides further accelerates the energy input into the baking chamber lining, which significantly cuts heating times.

A true

wood-fired oven bread

Offered as wood-fired oven bread and wood-fired oven bread rolls.

Low energy consumption

Short heating phase and recovery times

Centrally wood-fired

baking oven

Pellet burner for

untreated wood pellets.

Emission standards

are complied with

No soot build-up

in the baking chamber

Smaller footprint

Compared to brick-built wood-fired baking ovens.

Developed in cooperation with coop

Zyklotherm®

PELLADOR wood-fired deck oven series

Efficient baking powered by energy from sustainable sources

With the PELLADOR and the PELLADOR Zyklotherm®, WP has developed a series of wood-fired baking ovens that successfully harmonizes the advantages of a wood-fired baking oven and the demand of continuous production in modern bakeries. The underlying technology of the PELLADOR involves two pellet burners per deck. The gases produced in the combustion chamber are conducted directly into the baking chamber, where they burn with an open flame and heat up the chamber’s stone walls. The interval between baking processes is significantly reduced, thus ensuring high productivity.

Precise baking temperature control

In conventional wood-fired baking ovens, the temperature in the oven can only be controlled to a limited extent. The quality of the firewood is not always consistent, and once lit the wood cannot be stopped from burning down. The PELLADOR offers much more targeted temperature control.

Pellets are of consistently good quality. The preferred baking chamber temperature can be worked out from empirical values and the baking chamber’s control characteristics. The combustion process can be interrupted by stopping the pellet feed; there will only be a short after-burning. As a result, the baked products are of a controllable, consistently high quality.

Smaller footprint, increased productivity

Owing to the height of the baking chamber and unlike conventional wood-fired baking ovens, the PELLADOR can only have two to three baking chambers arranged one above the other. It is also possible to combine two PELLADOR of three decks each to form a PELLADOR tower with six decks. The baking chambers are loaded and unloaded with a loading system. The advantage: high production capacity on a small footprint.

Increased productivity

Reduced heating times and short

recovery times boost output.

Greater efficiency

Low pellet consumption

thanks to improved utilization

of exhaust gas energy.

Precise control

characteristics

Simple and precise

temperature regulation due to

inlet and outlet valves

for the exhaust gases.

Easier cleaning

No ash residue in the combustion chambers.

Green future

Sustainability and carbon neutrality through the use of untreated, renewable raw materials.

Loading and unloading of wood-fired deck ovens

Whether manual, semi-automatic or fully automatic - everything is possible!

Loading systems facilitate and accelerate the loading and unloading of deck ovens throughout the work process. The fully automatic OBER PRO II loading system takes care of loading the dough pieces and curing the finished baked goods at the end of the baking time. The semi-automatic PAGE and STEWARD loading systems increase the efficiency of the baking process. The manual solution JACK reduces the workload for employees during loading and unloading.

PELLADOR wood-fired baking oven – automation with OBER PRO II

The baking process itself is classic, typical for wood-fired baking ovens, working with decreasing temperature. All processes are controlled fully automatically. The system recognizes the respective state for each product, including the remaining baking time. Recipe and product management, oven and loading system are controlled centrally, saving on valuable time, increasing efficiency and cost-effectiveness, and delivering best baking results.

Digital production management WP BAKERY CONTROL

Quality through transparency

The central software for your bakery, suitable for all WP baking ovens (plug & play installation), storage, display and export of oven, recipe and production data.

WP BAKERY CONTROL – the digital production management for monitoring, control, facilitated recipe entry and transparency

Networking ovens with WP BAKERY CONTROL: Control centre with beneficial automation for supervision, control and easier recipe entering.

The most diverse product range in best quality

For juicy, crisp baked goods of consistent volume

Swabian spelt Seelen

Finn breads

Gassenhauer mixed rye breads

Large Roggenriese rye breads

Large Weizenriese wheat breads

Sunflower seed breads

Gnadenberg breads

Mixed grain breads

Service and support

We make sure that your production runs smoothly.

WP SERVICELINE

The WP SERVICELINE 24 is our guaranteed connection to the WP SERVICE and outside our opening hours to our emergency service:

Deutschland: +49 800 5 777 123

International: +49 1805 777 123

E-Mail: serviceline@@wpbakeryservice.de

Contact us

Any questions? We take care.

+49 9851 905-0

Within WP BAKERYGROUP were are THE manufacturer of deck ovens. We have been developing technical solutions for bakery businesses of any size for over 140 years.

We design, produce, install and service baking ovens, machines and systems worldwide for artisan bakeries just as well as for production facilities working on an industrial scale.

As specialists in the production of wood-fired ovens for bakeries, we would be happy to advise you on your personal project. Talk to us – together we will find the perfect solution for your success.