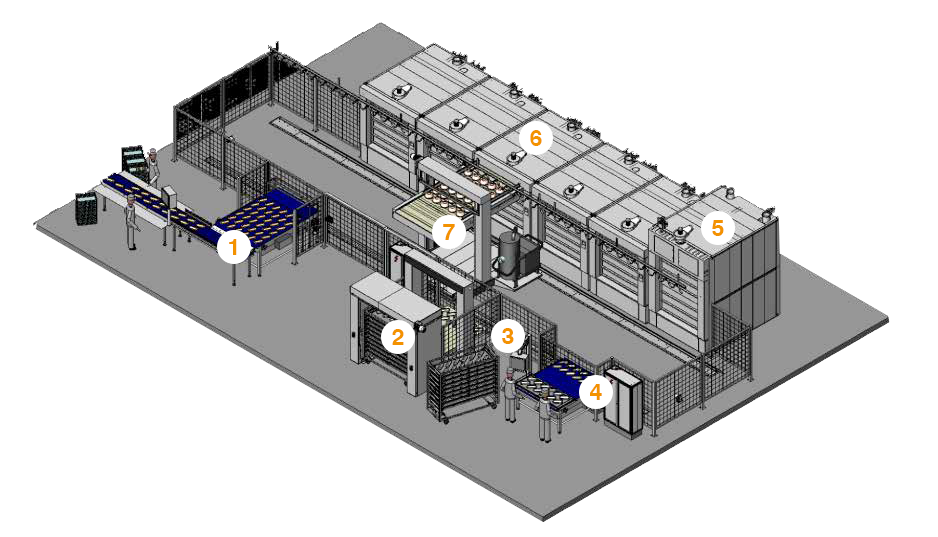

Fully automatic loading system

OBER PRO II

Fully automatic loading and automation

system for production ovens

system for production ovens

- Flexible product range

- 100 % reproducibility

- Energy efficiency through optimal fully automatic process control

Loading system OBER PRO II

Increased productivity through optimum oven utilization

The OBER PRO II is a fully automatic charging and automation system for production ovens. The modular design is possible for up to 8 production ovens. The entire plant can be controlled centrally.

5. Prebaking oven – MATADOR® MDV:

- All around interior baking stone lining

- High baking chambers

- Extremely high temperatures up to 350 °C

- Storage heat of the stones allows baking with decreasing temperature

- Artisanal top quality as in a wood-fired oven

6. MATADOR® MDV ovens:

- Up to 8 MATADOR® MDV deck ovens possible

- Deck oven depth 2,000 to 2,400mm

- Deck oven width 1,200 and 1,800mm

- Burner on the back of the oven

- Oven maintenance from the rear during operation of the entire OBER plant

- MATADOR® baking result guaranteed

- Energy-efficient thanks to ZYKLOTHERM® heating system

Performance, maximum benefits and modular options

- Product quality:

- Artisanal top quality with proven WP ZYKLOTHERM® baking stone oven technology

- Flexible product range, 100% reproducibility

- Performance:

- Integrated intelligent control system for loading and unloading processes

- Rationalization and reduced workload by eliminating heavy physical work

- Production reliability through WP BakeryControl and REMOTE DIAGNOSIS as well as BlueValue

- Energy efficiency:

- Energy efficiency through optimal fully automatic process control

Output volume

over 800 kg dough/hour

Selectable ovens/decks

up to 8/48

Operable baking area

200 m2

Traversing speed

vertical 1.1 m/sec

horizontal 0.13 to 1.8 m/sec

Loading speed

0.5 m/sec

Emptying speed

0.39 m/sec

Looking for a different product?

World of products

Flexible product range and 100% reproducibility

Slit rolls

Square rolls

Raisin rolls

Longmoulded rolls

Pastry

Baguette

Tin loafs

Soft wheat dough breads

Large Roggenriese rye breads

WP Bakery Technologies

+49 9851 905-0

Our sales team will gladly answer all your product-related questions.

Looking for a different product?

World of products