Vacuum cooling

The new vacuum process cools baked goods faster than all previously known methods. Oven-hot baked goods are cooled in just a few minutes. The cooled products are immediately available for further processing: Order picking/shipping, snack preparation, packaging or finishing.

Vacuum conditioning –

Freshness and tender crispness throughout the day

Vacuum technology continues to gain ground. Rapid cooling after baking by vacuuming enables long-lasting freshness, a tender crust and perfect crispness throughout the day. With the top product WP VACUSPEED® vacuum cooling, WP BAKERY TECHNOLOGIES meets the demands of the baking industry for more economy and efficiency.

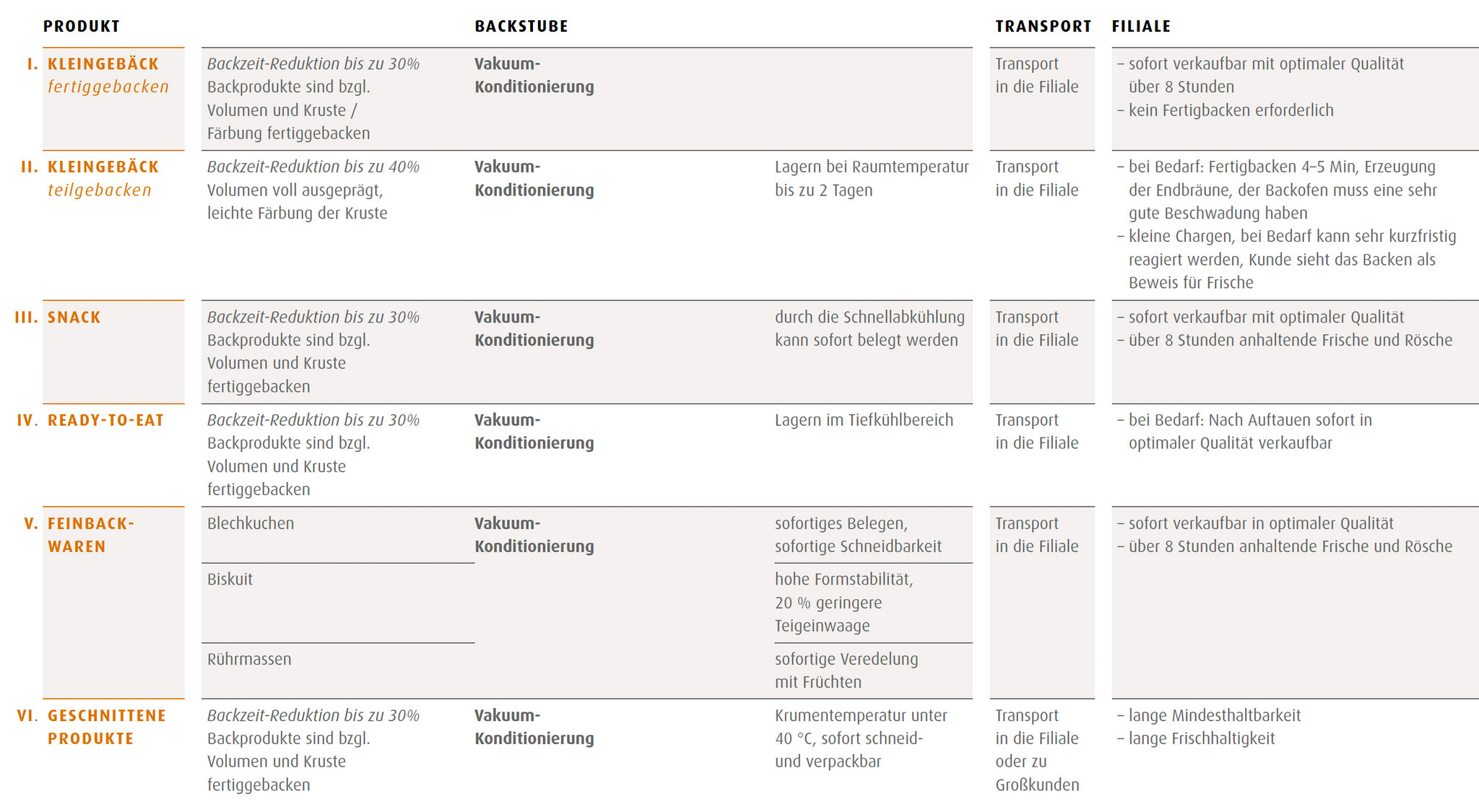

Vacuum technology opens up interesting perspectives for bakeries, because time- and labor-intensive in-store baking is being replaced by new, considerably more efficient processes: small bakery items are baked in the central production facility, but with a baking time reduced by up to 30 percent.

We offer VACUSPEED® cells with revolving or sliding door or as an airlock solution with two sliding doors to accommodate rack trolleys. VACUSPEED® artisan has been designed to accommodate rack trolleys. After completing the baking process, for example in a ROTOTHERM® Green rack oven, the rack trolley is manually loaded into the VACUSPEED® vacuum cell.

GOAL: Optimum and long-lasting freshness in the branch store with reduced effort to save energy and working time.

Increased efficiency

- Shift of production from night shift to day shift =

- Reduction of personnel costs and increase in employee motivation

- Response to shortage of skilled workers

- Reduction of weekend work = Reduction of personnel costs

- Optimized utilization of production resources

- Improved sustainability/reduction of carbon footprint

- Increased productivity

![[Translate to Englisch:] Vakuumkühlung VACUSPEED artisan [Translate to Englisch:] Abbildung der Vakuumkühlzelle VACUSPEED® artisan](/fileadmin/wpl/produktwelt/kuehlen/vacuspeed-artisan/WP-Vacuumkuehlung-VACUSPEED.jpg)