Software

WP BakeryControl

WP BakeryControl creates transparency and clarity in your production. The software helps you optimize processes and identify potential for improvement with the aim of boosting productivity, improving employee deployment, and cutting energy costs. Production data is the basis for well-founded decision-making to increase productivity and optimize the sustainable use of resources.

Bakery 4.0:

Plan. Identify. Improve.

It’s that simple!

Production planning is a complex task involving many constantly changing parameters. Drawing up a production plan, scheduling baking ovens and employees asks for a lot of experience. Planning the optimum oven start, baking batch on batch and avoiding idle times are important factors.

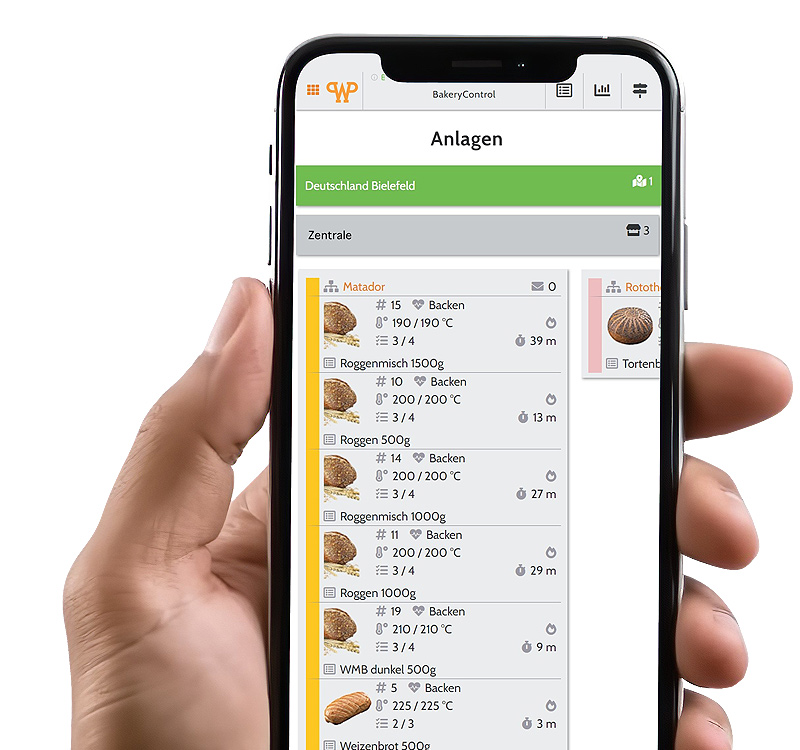

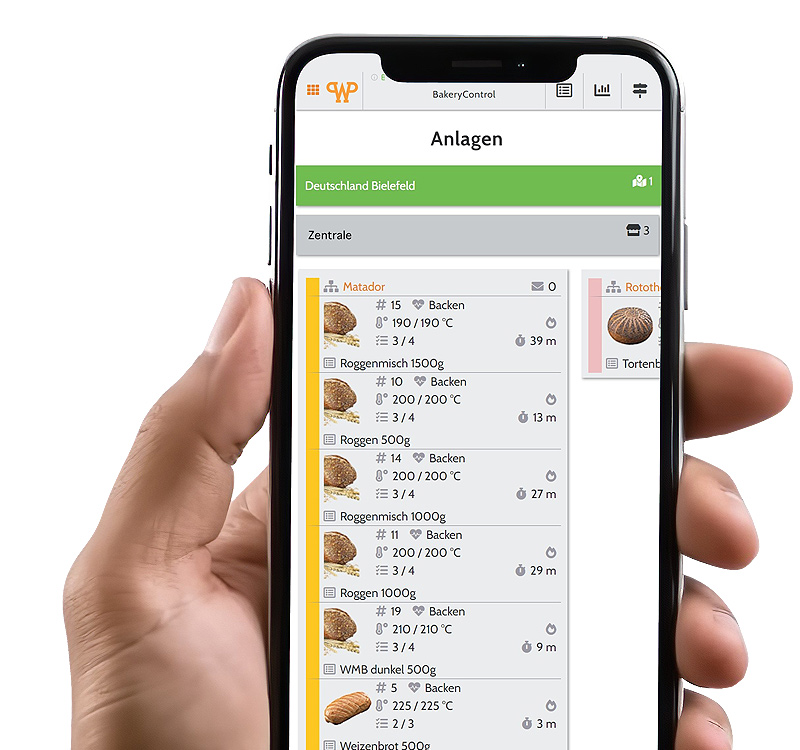

The WP BakeryControl software is your virtual control station. Production data is visualized and evaluated, deviations are identified and can be optimized – both stationary and mobile.

All relevant parameters are incorporated in batch reports, statistics, and summaries. The WP BakeryControl software helps you save on energy resources by drawing on your experience and precisely fine-tuning all relevant factors – making no compromises on the quality of your baked goods.

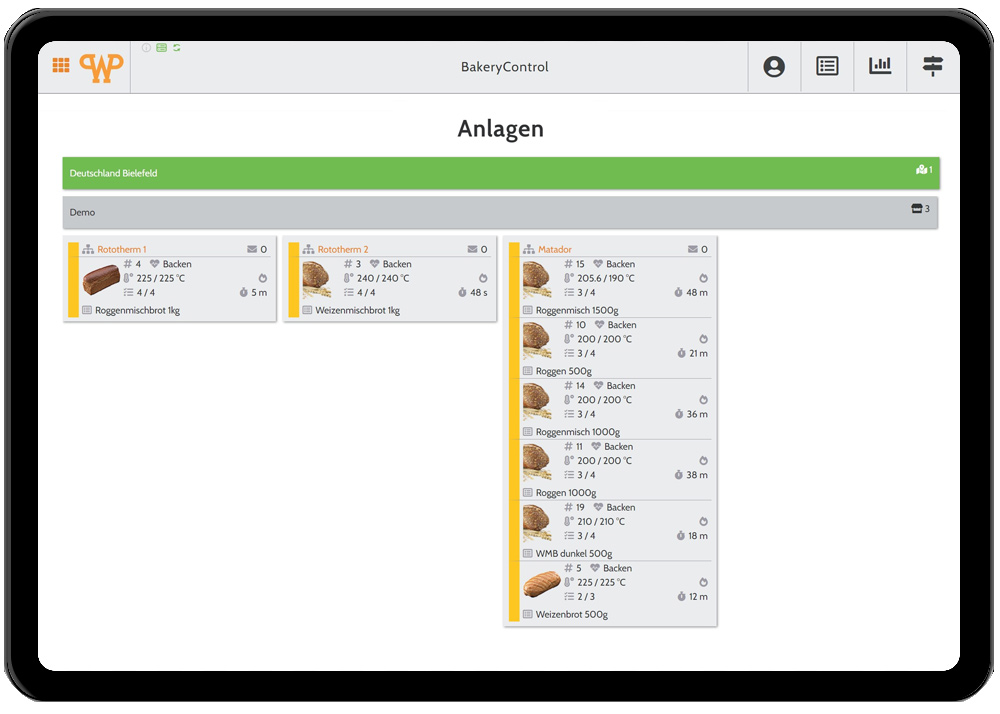

WP BakeryControl control station

The centerpiece for your production planning in the bakery

Monitoring and control of production and operating processes. Optimized production through networking and transparency. WP BakeryControl is the basis for business decisions in production.

Networking

Networking of baking processes

and production sites

Quality assurance

No compromises when it comes

to the quality of your baked goods

for a plus in freshness.

Transparency

& assistance

Clear display of

current production with

access to details such as

target/actual comparisons

of temperatures and

consumption.Idle times and

potential for improvement

are immediately identified.

Procedures deviating

from the defined process

become transparent.

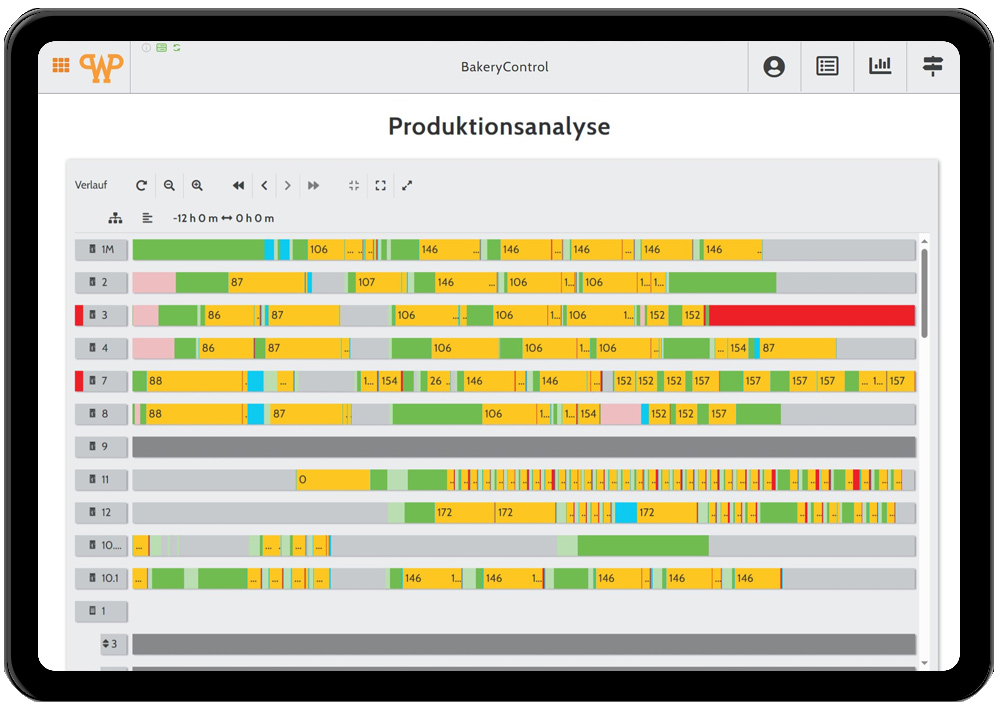

Optimized production

Statistics of energy consumption

per department, production site,

oven and baking recipe for

detailed evaluation. Goal:

Cost cutting and efficient

employee deployment

through optimized

production planning

The functions of WP BakeryControl

A combination of hardware and software

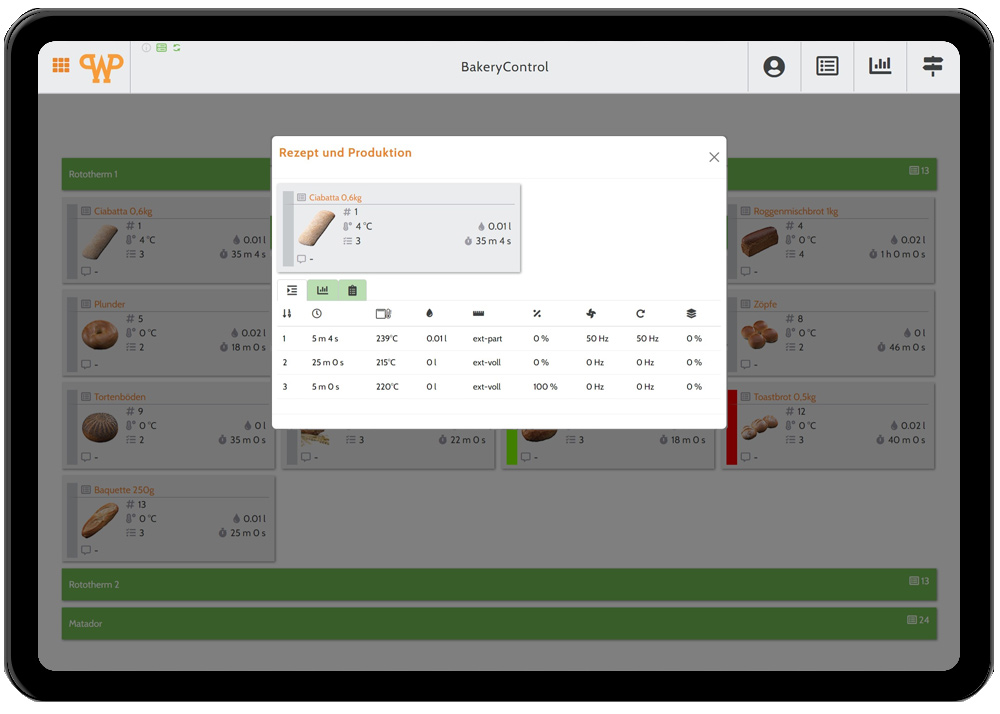

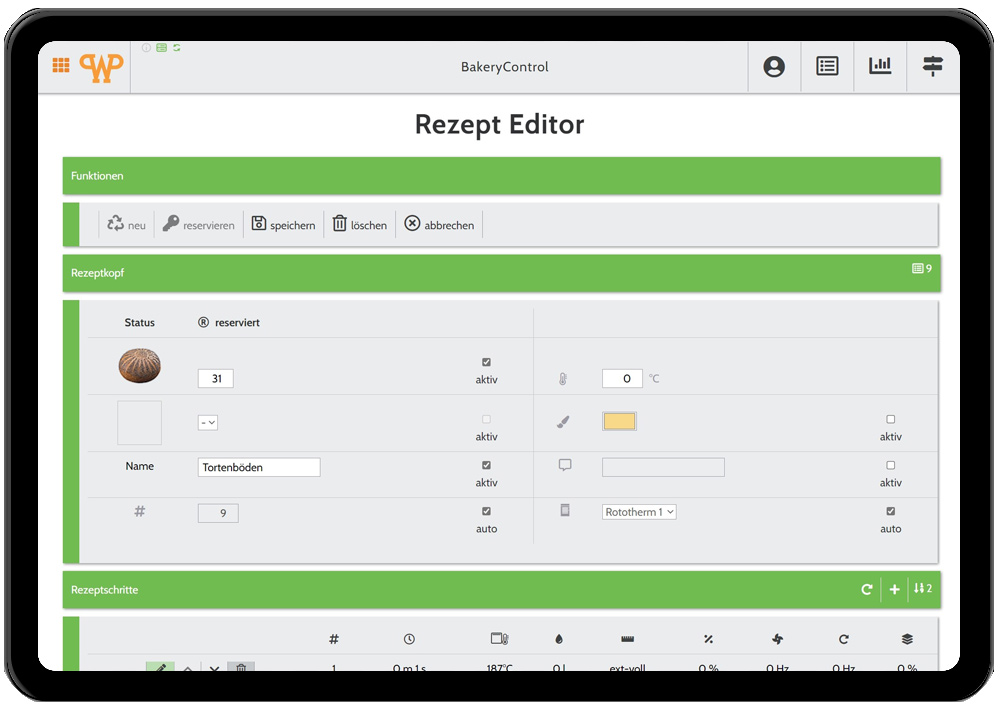

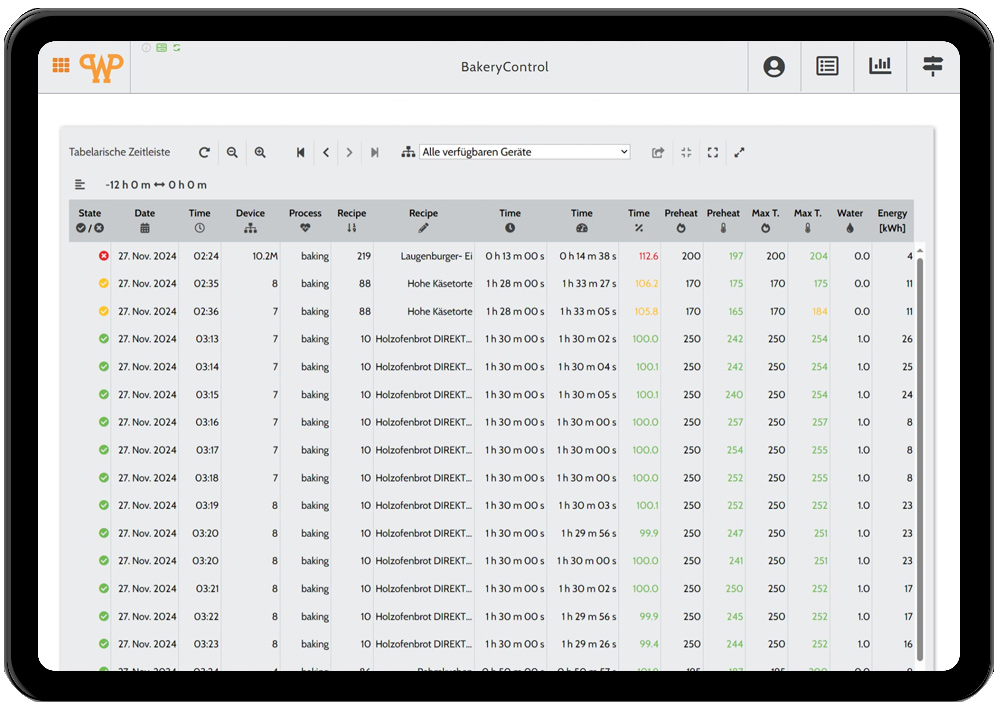

Controllers, sensors and scanners continuously supply data from the production chain. The WP BakeryControl software documents, stores and analyzes this information in real-time. A production history shows the timeline of all baking processes. Idle times and potential for improvement are immediately identified. Quality defects such as early loading, or deviations from the baking process are identified and made transparent, thus securing the quality of your baked goods.

Managing production digitally

Production overview and recipe management

Production

Machine status, overview, temperatures, product icons, recipes, and times

Recipe overview

View recipes

Recipe editor

Creating, managing, editing, adjusting, and copying recipes from one oven to the other

Documentation, analysis, evaluation

for continuous process optimization

Analysis and optimization

Production analysis, baking time optimization, recipe sequences, energy consumption, runtimes

Documentation in table form

PDF and CSV export via e-mail and WP DIGITAL PORTAL: overview and individually defined time periods, summary of data and quick identification of faults

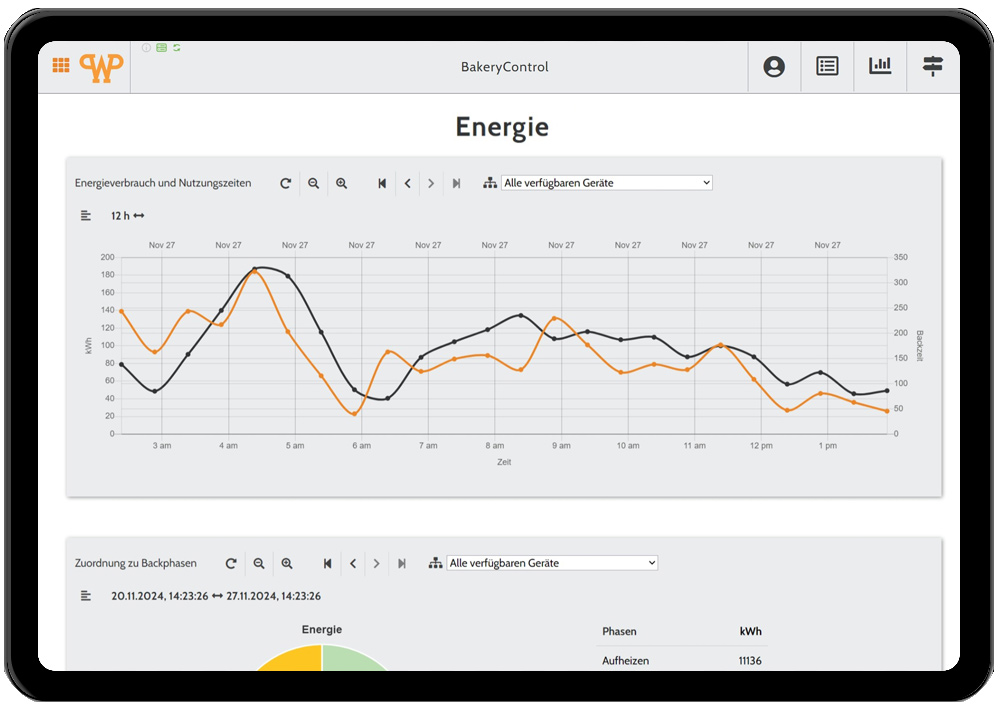

Energy analyses

Energy consumption chart for baking phases, comparison of energy consumption and utilization

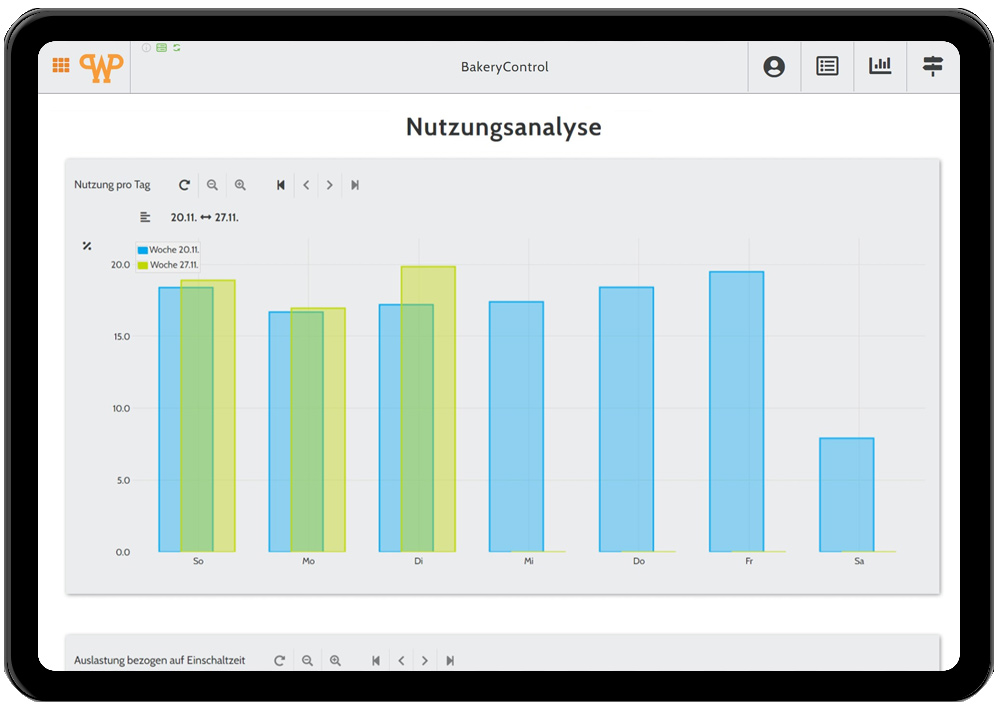

Weekly comparison

Weekly analyses, fault history, machine utilization

WP BakeryControl:

consistent planning and optimized production

Process optimization

Optimization of production and

oven loading as a permanent

improvement process.

Production networking:

360° view

Networking of all

baking processes and

production sites,

access via mobile devices

or stationary computers,

open interfaces to

other systems.

Saving on

energy

Statistics of energy

consumption per department,

oven and baking recipe

for detailed evaluation.

Which improvement brings

which benefit?

Consistent

product quality

Quality and freshness of the

baked goods are ensured.

More efficient

production

Less consumption and efficient

staff deployment through

optimized production planning

as well as identifying and avoiding faults.

WP BakeryControl – digital production management for monitoring, control, recipe management, and transparency.

Networking baking ovens with WP BakeryControl: The virtual control station for monitoring, control, and recipe management.

Service and support

We make sure that your production runs smoothly.

WP SERVICELINE

The WP SERVICELINE 24 is our guaranteed connection to the WP SERVICE and outside our opening hours to our emergency service:

Deutschland: +49 800 5 777 123

International: +49 1805 777 123

E-Mail: serviceline@@wpbakeryservice.de