History

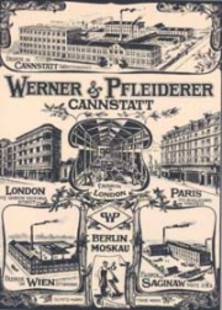

1880

The joint enterprise Werner & Pfleiderer is entered on the Commercial Register of the Cannstatt Local Court. In the beginning, the company makes mixing machines but the market and army provision offices soon start demanding complete systems for making rusk. Pfleiderer initially buys the necessary dough rollers, cutting machines and ovens from England. Soon afterwards the company starts making its own.

1893

The company Werner, Pfleiderer & Perkins Ltd. is established in London. Perkins supplies the special steam pipes for ovens production. The works in Cannstatt has the suffix "Cannstatt Steam Baking Oven Factory" added to its trading name. At the same time, Werner adds ribbon proving cabinets and taper round-moulders to the production range. The clientèle includes not only customers in the food industry but also chemical, paint and explosives manufacturers.

1918

The company has lost 74 employees in the war. The plants in Britain and the USA are compulsorily expropriated. The British firm Joseph Baker & Sons buys the subsidiary in Saginaw and the British subsidiary, Werner, Pfleiderer & Perkins, and forms Baker Perkins Ltd. Numerous foreign branches have to be closed. The major part of the sales market is lost.

1938

Zyklotherm heating is introduced into baking oven design. It involves a central gas or oil-fired heater that produces hot air as the heat conduction medium, which is then controllably directed via channels around the baking or drying chamber. This enables precise temperature regulation. It also reduces operating costs.

1939

The company makes machines for field bakeries, supplies mixers for explosives, artificial silk and rubber, and manufactures parts for artillery weapons, aircrafts and rocket tail units (for the V II). The proportion of arms-related production is less than 20 %. Many former employees are at the frontline. In their place, so-called "foreign workers" are employed.

1949

Otto Fahr takes over the reins of the company again and his eventual successor, Helmut Steinmann, joins the business. Even though synthetic rubber production in Germany has to be shut down, WP's business with the chemical, plastics and rubber industries is booming. The plasticizer for PVC production is invented and establishes itself as the standard.

1953

The first Matador oven is delivered. The MATADOR remains the most successful deck baking oven on the market to this day.

1964

Production of the MATADOR moves from Stuttgart-Feuerbach to Dinkelsbühl in Bavaria. The plot and buildings previously used as a sawmill are put to new use and reorganized in the years that follow, and finally replaced by new production halls and a new office building. New staff are recruited through newspaper, poster and cinema advertising and trained at company headquarters in Feuerbach.

1992

Werner & Pfleiderer sets new standards in the baking sector with the still unrivaled, computer-controlled OBER loading unit (a name that has since become synonymous with automatic loading of deck baking ovens), the first automatic tray loader for roll baking systems, the Robomatic, and the first flour-dust-free bread baking system.

2014

The WP MATADOR STORE Green instore oven is winner of the Südback Trend Award. The coveted innovation award for forward-looking ideas in the baking industry.

In the same year, the Dinkelsbühl location celebrates its 50th anniversary.

2015

The WP MATADOR STORE Green instore oven is winner of the Südback Trend Award. The coveted innovation award for forward-looking ideas in the baking industry.

In the same year, the Dinkelsbühl location celebrates its 50th anniversary.

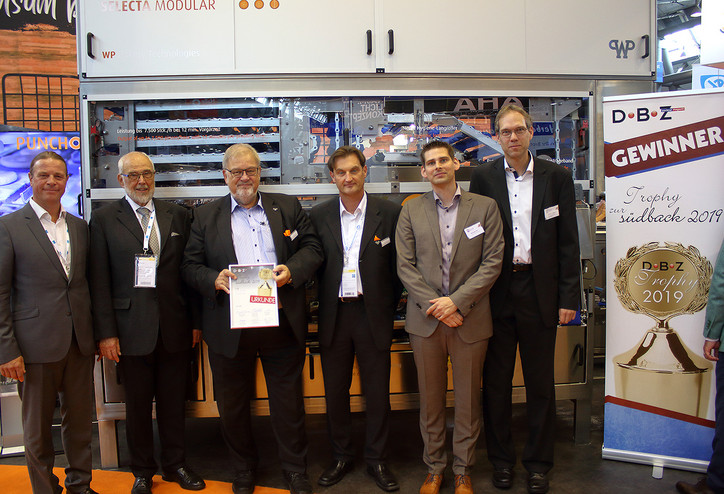

2019

PUNCHO hole punch wins Südback Trophy 2019. Whether it's donuts, donuts or bagels: with the PUNCHO hole punch, artisan bakeries can easily and inexpensively expand their range with a variety of perforated products. The punching module, which is easy installed, convinced the top-class jury as an innovative new development for the bakery trade.