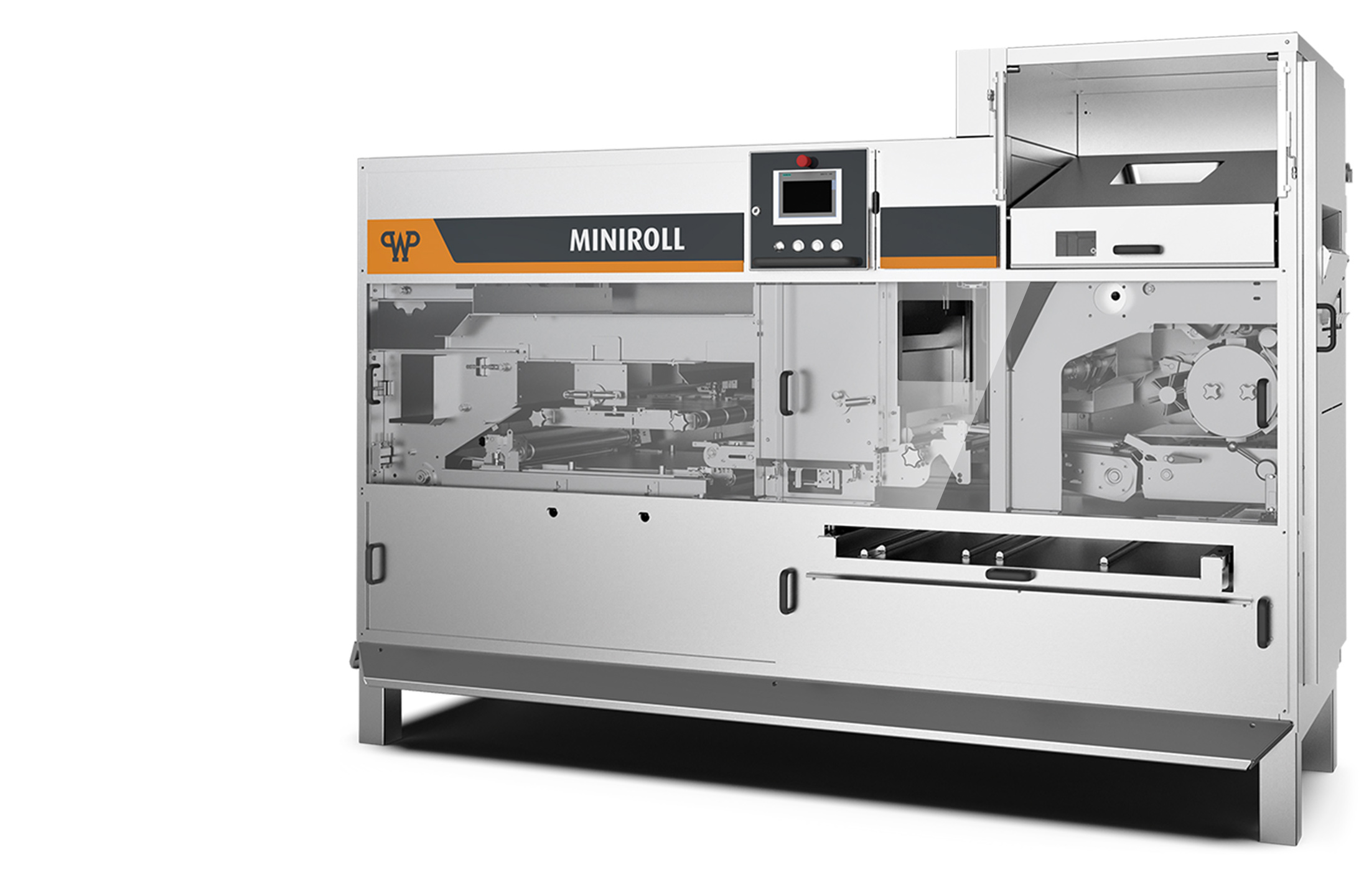

Roll baking system

MINIROLL

high capacity in the smallest space

The compact system for small bakery items in perfect craftsmanship quality. The large weight range of the integrated MULTIMATIC dough divider allows for great product variety.

The all-rounder

in the bakehouse

This compact system produces long-rolled rolls, smooth round rolls (also cylindrical), small baguettes, but also buns for hamburgers or hot dogs with a dough weight of 35 g to 150 g.

The interchangeable pressure boards and the driven top belt ensure variety. And what’s more: In green mode, up to 9,000 pieces can be produced per hour. Quite maxi, our MINIROLL!

A gentle dough dividing and molding process has a decisive effect on the quality of your baked goods. For this reason, the MULTIMATIC head machine, which is gentle on the dough, accurate in weight and flexible, has been integrated into the compact MINIROLL form baking system.

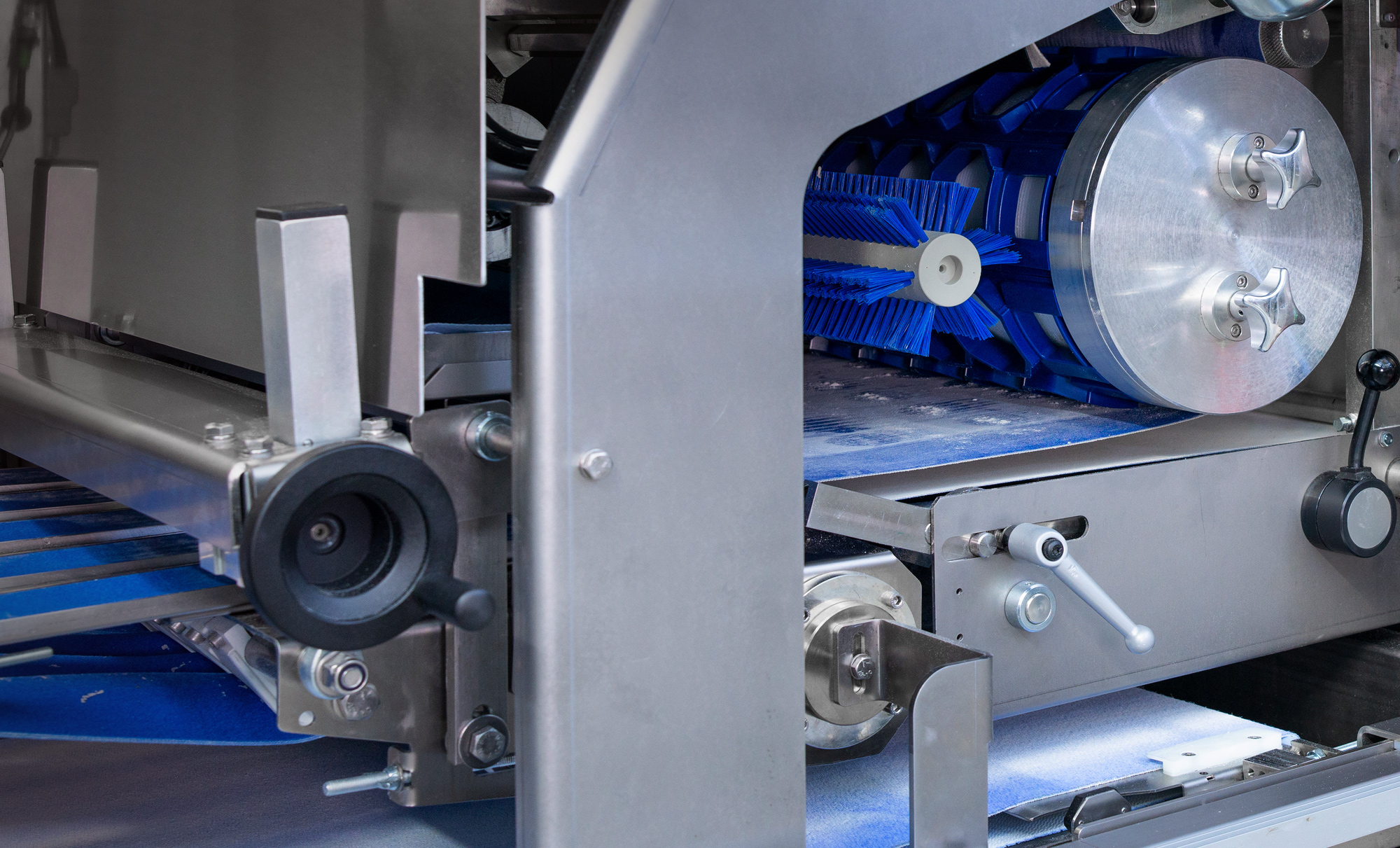

Interchangeable pressure boards and the driven top belt

ensure variety of bakery items in the compact roll baking system

Equipment

- 3- to 6-row system of 600 mm or 800 mm width

- Weight range from 35 g to 150 g

- Manual pressure adjustment

- Automatic weight adjustment

- Hanger drying

- Climate control in the proofing cabinet

- Intense degermination station

- Variable depositing unit for proofing boards of different Euro sizes

- Depositing unit with end position change

- Counter

- Array of pressure boards for product maximum variety

- Bypass belt for green mode

- Integrated chamber drum shelf for maximum 3 chamber drums

Extended weight range:

The integrated MULTIMATIC C or MULTIMATIC PRO head machine

Most gentle

dough handling

With gentle drum molding

system, adjustable molding belt,

and variable molding intensity

High hopper volume

Holding capacity 40 kg

Photocell technology

Easy and safe operation of the system

Simple product change

With automatic weight adjustment

Extended weight range

Thanks to double piston system

Hygiene

Dough-handling machine

parts are separated from

the drive mechanism, and

thus easy to clean

Compact MINIROLL roll baking system with integrated MULTIMATIC drum round molder

A gentle dough dividing and molding process has a decisive effect on the quality of your end products. For this reason, the both gentle on the dough and flexible MULTIMATIC C resp. MULTIMATIC PRO head machine has been integrated into the compact MINIROLL form baking system.

WP roll baking systems – Technology that inspires!

Advanced working processes for optimum quality and content staff

WP has been a partner to the baking trade for generations. Our expertise and the exchange with the baking trade worldwide have helped our machines mature and become what they are today. Working with them is pure joy.

Simple operation

- Intuitive Siemens touch control

- All functional areas are

clearly visible - Weight and product change

with a few simple steps - High level of operational

safety using additional

signal lights

Easy to clean

- Easy, time-saving cleaning

- Free access to all functional areas

- Dough-handling parts are

separated from the drive mechanism - Ample ground clearance

- Majority of dough-handling

parts suitable for machine cleaning

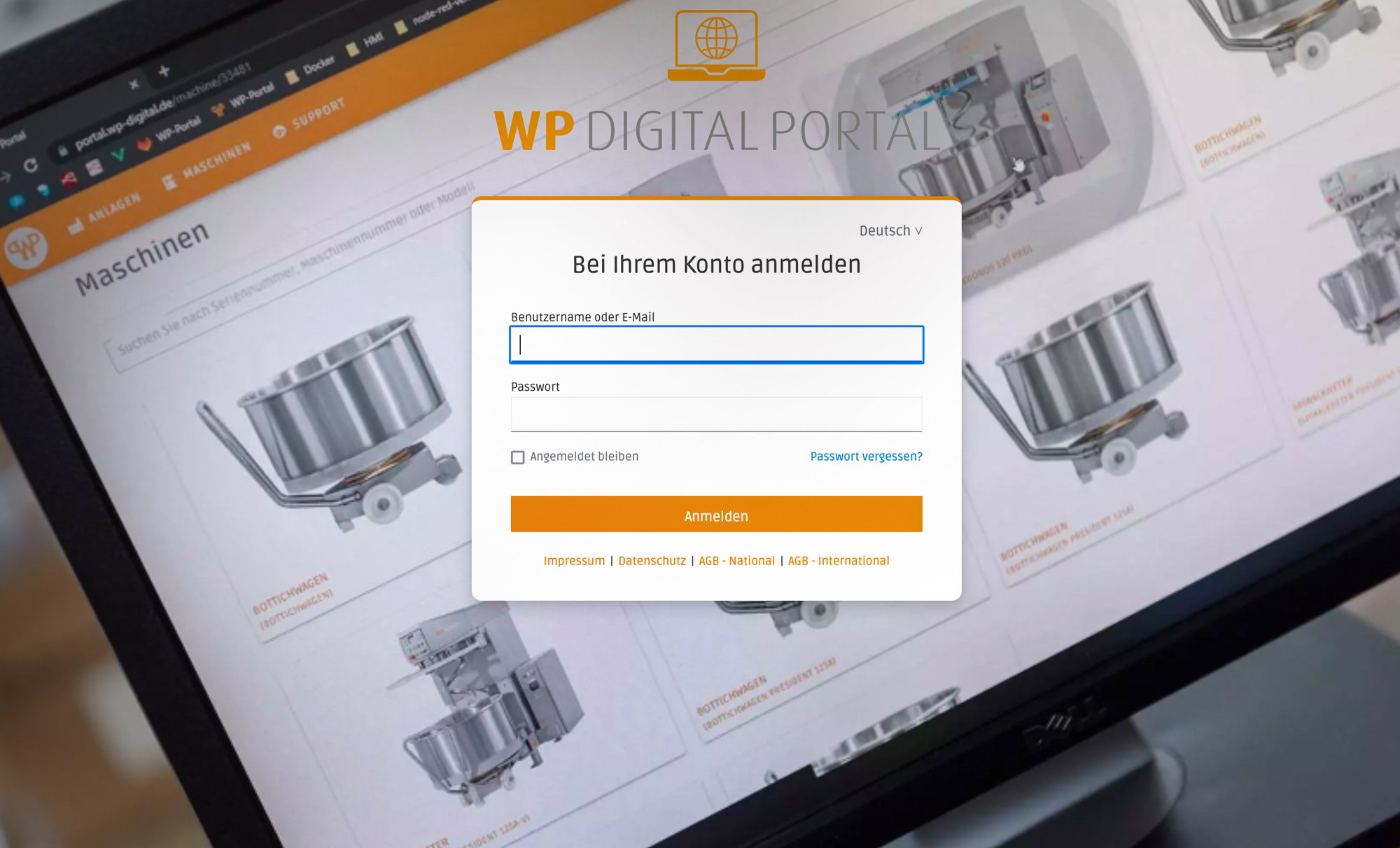

Digital machine file

- Direct access to machine

and system information - Online spare parts, wear

parts and service orders

Motivated employees

- Ergonomic workstations reduce

physical strain to a minimum - Relief from monotonous routine tasks

- Improve working environment

WP DIGITAL PORTAL: Register now!

Safeguarding process quality, boosting efficiency, cutting costs. Take the first step, sign up to the WP DIGITAL PORTAL for free, and register your ovens and machines. The WP DIGITAL PORTAL grants access to machine and system information as well as service functionalities in the web browser. The future is digital!

Performance features

pieces/hour

max. 9,000 pieces/hour

3-row: 1,800 (4,500*)

4-row: 2,400 (6,000*)

5-row: 3,000 (7,500*)

6-row: 3,600 (9,000*)

* Capacity in green mode

(The capacity is depending

on dough and weight)

weight range (g)

35 g to 85 g,

35 g to 150 g optional

rows

Dough molder

- Working width 600 mm and 800 mm

- 3- to 6-row

The compact bread roll baking system with high capacity in the smallest space

The interchangeable pressure boards and the driven top belt ensure variety.

Easy to operate, freely programmable,

perfect visibility at all time

The Siemens touch control is easy to operate, freely programmable and clearly visible at all time.

Large touch display

Easy operation

Master control

password protected

Depositing unit

freely programmable

Remote maintenance

Networking and efficient remote diagnosis as well as remote maintenance possible. Data backup to flash card or USB flash drive.

User-friendly, production-reliable, always at your fingertip

WP machines and systems come equipped with a standardized control system. Identical menu navigation and uniform use of pictograms, colors and processes greatly simplifies operation and prevents errors. As an option, we offer a powerful and safe remote diagnosis and maintenance feature.

Hygienic safety

A clean affair!

Hygiene starts with the design of machine and system. Easy to clean or removable components, smart solutions and innovative materials ensure a maximum level of hygiene!

Hygienic safety

Shortest cleaning time

Maximum value retention

- Guide plates, casing, climate modules, long rolling and stamping tools, flour duster and exchangeable modules are easy to mount and remove

- All dough-handling parts and all plastic components in hygienic design version

- High ground clearance to facilitate cleaning

- Window on both sides can be opened and removed

Most diverse product range in best baking quality

To keep your product range attractive at all times.

Smooth round roll

Double roll

Raisin roll

Long rolled roll

Hamburger bun

Mini baguette

Ball donut

Service and support

We make sure that your production runs smoothly.

WP SERVICELINE

The WP SERVICELINE 24 is our guaranteed connection to the WP SERVICE and outside our opening hours to our emergency service:

Deutschland: +49 800 5 777 123

International: +49 1805 777 123

E-Mail: serviceline@@wpbakeryservice.de