![Vacuumcooling VACUSPEED® artisan [Translate to Englisch:] Abbildung der Vakuumkühlzelle VACUSPEED® artisan](/fileadmin/wpl/produktwelt/kuehlen/vacuspeed-artisan/WP-Vacuumkuehlung-VACUSPEED.jpg)

Vacuum cooling

VACUSPEED®

artisan

throughout the day

![Vacuumcooling VACUSPEED® artisan [Translate to Englisch:] Abbildung der Vakuumkühlzelle VACUSPEED® artisan](/fileadmin/wpl/produktwelt/kuehlen/vacuspeed-artisan/WP-Vacuumkuehlung-VACUSPEED.jpg)

Thanks to the new Vacuspeed, you can stay cool, just like your baked goods. Optimum baked goods with long-lasting freshness for your branch stores. The new vacuum process cools baked goods in just a few minutes, ensuring lasting crispness and stability. The baked goods are unaffected by changing weather conditions and can be further processed immediately. This cuts energy and personnel costs on many levels and delivers even higher product quality!

Vacuum technology is gaining ground

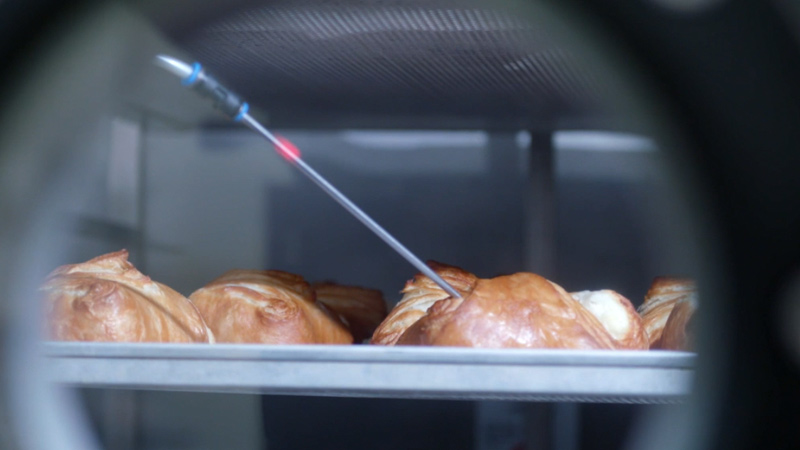

Increased economy and efficiency for the baking industry: Vacuum technology opens up interesting perspectives for bakeries, because time- and labor-intensive in-store baking is being replaced by new, considerably more efficient processes: small bakery items are baked in the central production facility, but with a baking time reduced by about 30 percent.

Extended shelf life and more appealing products throughout the day: Rapid cooling after baking by vacuuming enables long-lasting freshness, a tender crust and perfect crispness throughout the day.

Perfect integration in the production process: We offer VACUSPEED® cells with revolving or sliding door or as an airlock solution with two sliding doors to accommodate rack trolleys.

System variants

VACUSPEED® vacuum cells from WP Bakery Technologies have been designed to accommodate rack trolleys. We offer VACUSPEED® cells with revolving or sliding door to accommodate rack trolleys. VACUSPEED® artisan can be integrated manually or as a WP VACUUM COOLING module in fully automatic loading and automation systems of multi-deck and tunnel ovens.

VACUSPEED® artisan with revolving door

Design version

With revolving door and integrated pump stand

Products

Type 14.5.10 for up to 10,000 pieces / hours

Type 26.10 for up to 20,000 pieces / hours

(capacity dependent on product size and cycle time)

Possible system configuration

WP ROTOTHERM® Green

+ WP VACUSPEED ® artisan

VACUSPEED® artisan with revolving door

Model

With revolving door and external pump stand

Products

Type 14.5.10 for up to 10,000 pieces / hours

Type 26.10 for up to 20,000 pieces / hours

(capacity dependent on product size and cycle time)

Possible system configuration

WP ROTOTHERM® Green

+ WP VACUSPEED ® artisan

VACUSPEED® artisan with sliding door

Model

With sliding door and integrated pump stand

Products

Type 14.5.10 for up to 10,000 pieces / hours

Type 26.10 for up to 20,000 pieces / hours

(capacity dependent on product size and cycle time)

Possible system configuration

WP ROTOTHERM® Green

+ WP VACUSPEED ® artisan

VACUSPEED® artisan with sliding door

Model

With sliding door and external pump stand

Products

Type 14.5.10 for up to 10,000 pieces / hours

Type 26.10 for up to 20,000 pieces / hours

(capacity dependent on product size and cycle time)

Possible system configuration

WP ROTOTHERM® Green

+ WP VACUSPEED ® artisan

VACUSPEED® artisan with sliding door as a push-through solution

Model

With sliding door as a push-through solution

Products

Type 14.5.10 for up to 10,000 pieces / hours

Type 26.10 for up to 20,000 pieces / hours

(capacity dependent on product size and cycle time)

Possible system configuration

WP ROTOTHERM® Green

+ WP VACUSPEED ® artisan

Advantages of VACUSPEED artisan vacuum cooling

Good-bye night shift!

WP VACUUM CONDITIONING

This vacuum process takes the cooling of oven-hot products to a new dimension: cooling baked goods faster, saving energy. The products have a longer lasting crispness, remain firm longer, and are immediately ready to cut. Shelf life is extended by up to three weeks. How is this possible?

The 7 special features of the WP VACUSPEED®

Vacuum conditioning means product optimization for maximum quality

Features

Features

Features

Features

Features

Designing bakery processes with vacuum technology

Thorsten zur Horst reports on his personal experiences and why he would choose this technology again and again.

Story of Success

Technical properties of the VACUSPEED artisan

Sturdy design for long service life

Fast and safe cool-down

- Two-stage pump technology for fast and safe cool-down.

Sturdy design

- Use of high-alloy V2A stainless steel and high wall thicknesses for a sturdy design and long service life, despite high alternating stresses imposed by the vacuum.

High hygiene and safety standards

- Condensate drainage in the chamber for improved hygiene and reduced risk of slipping

- Easy to maintain and clean.

The choice is yours

- External or integrated pump stand

- Revolving or automatic opening sliding door

“DRIVE THROUGH” version

- Drive through version with a sliding door each at the front and rear acts as an airlock, for example for clean air areas.

Control via touchscreen (Siemens)

- For programming complex procedures.

ROTOTHERM Green rack oven and VACUSPEED – a perfect match

Baking with ROTOTHERM® Green reduces baking times by up to 30 percent. Which oven technology makes theROTOTHERM® Green in combination with the VACUSPEED® so efficient? What makes batch-on-batch baking possible, and how does the air flow in the oven have an effect on the reproducibility of product quality? Find out more about the functional principles of theROTOTHERM® Green here.

What’s new?

Stay up to date with the WP BAKERYGROUP newsletter.

Subscribe to our newsletter

Do you want regular information about WP products and innovations?

Service and support

We make sure that your production runs smoothly.

WP SERVICELINE

The WP SERVICELINE 24 is our guaranteed connection to the WP SERVICE and outside our opening hours to our emergency service:

Deutschland: +49 800 5 777 123

International: +49 1805 777 123

E-Mail: serviceline@@wpbakeryservice.de

Contact us

Any questions? We take care.

+49 9851 905-0

We have been developing technical solutions for bakers for over 140 years. Our experience and process expertise, from dough preparation to baking, puts us in control of the entire production process. We can thus develop systems that fit perfectly into your production and open up new opportunities for you: Efficiency and increased productivity for baked goods of maximum artisan quality while keeping a small footprint.

VACUSPEED vacuum cooling sets new standards in your production: Fresher, longer-lasting products with a shorter and more economical production process. We would be happy to advise you on your personal project. Talk to us! Together, we will find the perfect solution for your success.