Rack oven

ROTOTHERM

Green

With a certified reduction in energy consumption by 30 %

compared to the RE 1020 predecessor model.

The ROTOTHERM Green rack ovens with rotating rack trolleys show how this can be done. They significantly determine the quality of the baked goods and influence the profitability of your business through energy consumption. Excellent baking results with proven 30 % lower energy consumption compared to the previous RE 1020 model. In addition to oil and gas firing, all ROTOTHERM Green oven sizes are also available in an electric version.

Energy-efficient baking

without compromise

An oven with the best conditions: product quality and cost-effectiveness start with the design. With innovative materials and optimized insulation, the ROTOTHERM Green rack oven achieves unparalleled insulation properties and extreme longevity. The new design also allows for optimized airflow for even energy distribution. This leads to higher product quality while saving energy.

Perfect temperature curves for the best products and shorter baking times: Innovative heating ensures a consistent target temperature. WP THERMOGATE enables the oven to heat up immediately when baking from shot to shot - and thus a higher baking output per hour. In addition, the particularly even steam formation ensures more volume and juicy baked goods.

More economical baking and better production: With 10% shorter baking times, you optimize your margin, the fully automatic oven control supports a smoother production process - and the increased longevity of the oven guarantees both - production reliability and investment security.

Rack oven variants

ROTOTHERM Green

baking area: 10.0 – 13.8 m²

heated by: oil/gas/electric

Best-quality baking results with high energy efficiency

ROTOTHERM Green Drive Through

baking area: 10.0 – 13.8 m²

heated by: oil/gas/electric

The rack oven as drive through version or as

hygiene lock

ROTOTHERM Green Heavy Duty

baking area: 20.0 – 22.0 m²

heated by: oil/gas/electric

The heavy-duty worker among the ROTOTHERM Green series

Rack oven ROTOTHERM GREEN

with or without steam hood

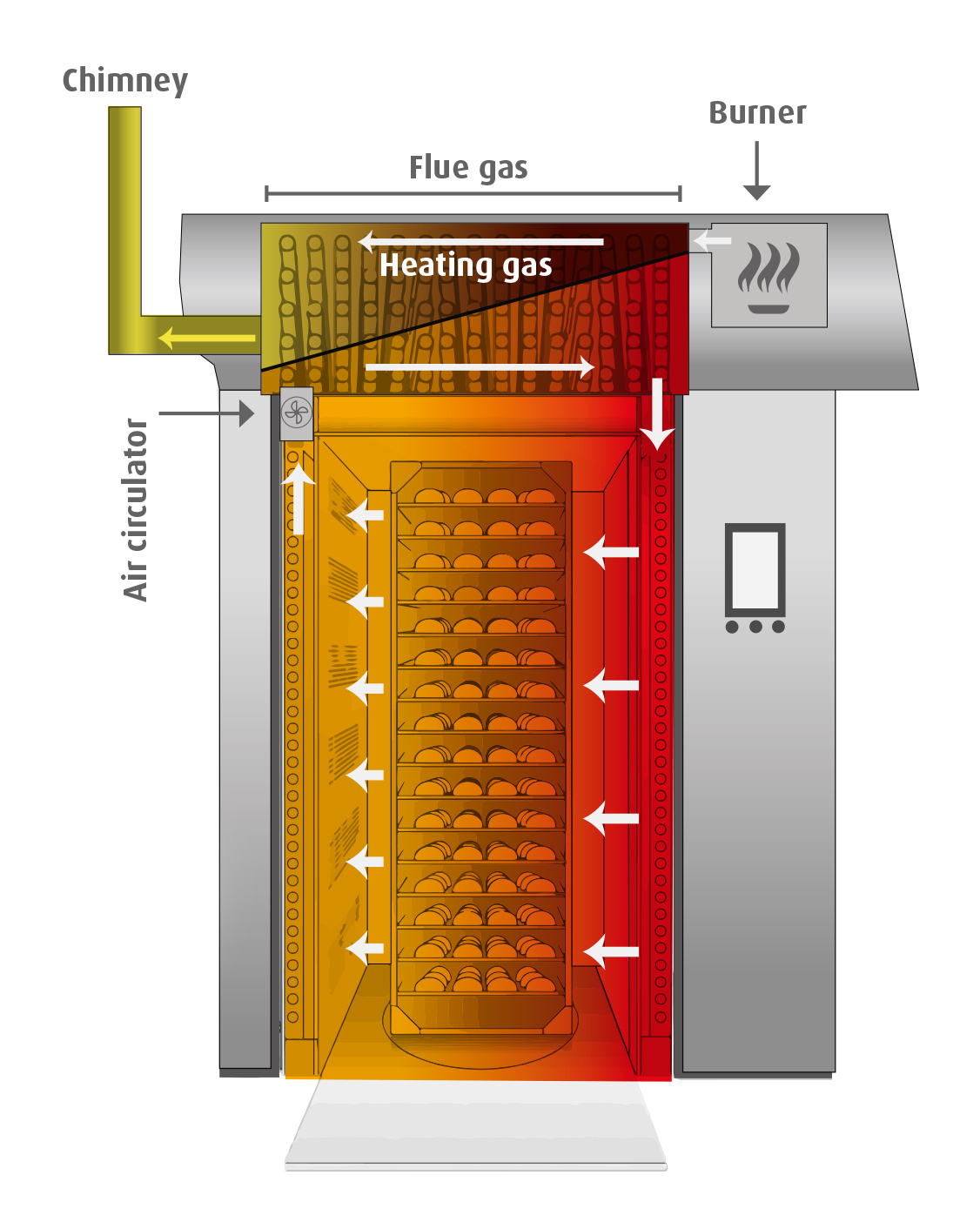

The "motor" of the rack oven ROTOTHERM Green

Oven tuning with efficient heat exchanger

State-of-the-art engines with smaller cubic capacity thanks to new technologies deliver top performance – and consume even less fuel. WP engineers have very intelligently transferred this successful trend to the ROTOTHERM Green.

Quality of bakery items

Crisp, tender flaky crust,

juicy crumb thanks to

optimum application of

energy.

Service life

Durable thanks to

special WP steel.

Saving effect

30 % less energy

consumption, certified

(compared to the previous

RE 1020 model from

2012).

Amortization

Lowest energy

cost per piece.

A smaller burner with reduced connected load and combined with an innovative heat exchanger serves as the "motor" of the rack oven. Optimized technology that uses less fuel and yet achieves excellent baking results at the same time.

This works for a very simple reason:

The efficient heat exchanger now exploits energy that previously escaped unused through the chimney to the maximum.

THE ROTOTHERM Green offers great saving potential

30 % less energy consumption compared to the previous RE 1020 model from 2012. Certified!

The quality turbocharger WP THERMOGATE

For real batch-on-batch baking

Just as a turbocharger multiplies the sprint power of a sports car, does WP THERMOGATE power up the performance of the oven heating. This considerably shortens heating time! It allows you to produce more baked goods per hour with real batch-on-batch baking. The quality turbocharger renders the production process faster and improves quality at the same time. With WP THERMOGATE you are bound to produce premier class baked goods.

Juiciest

baked goods

Juiciest baked

goods with beautiful

crust break and

more volume.

10 % shorter

baking time

10 % shorter baking

time thanks to

optimized application

of energy.

Batch-on-batch

baking

Real batch-on-batch

baking.

Increased baking

capacity

Increased baking

capacity per hour.

No overheating

Burner protection

through by-pass,

no overheating of

the burner.

The right rack oven for best quality baking items

Optimized air flow ensures consistent product quality

The direction is right with the ROTOTHERM Green! The air is accurately directed onto the product over the entire jet wall. The result at every point of the baking trolley is constant baking quality. Moreover, the optimized air flow applies more energy on the dough pieces, shortens the baking time and makes your baking items particularly juicy.

Consistent

quality

Consistency and

reproducible quality.

Optimum

steam

Optimum distribution

of heat and steam.

Juicier baking

items

The air is accurately

directed onto the product

over the entire jet wall

Reduced baking time

More output per hour.

Optimum air flow for uniform and

reproducible product quality

Consistent baking results at every point of the baking trolley.

Excellent steam for highest demands

Rich steam creates juicy baked goods

ROTOTHERM Green has an excellent vapor performance. Its steaming device really steams it up! Its rich steam creates juicy baked goods. Visually and in terms of flavor a delight your customers will love!

Juicy baked

goods

Particularly

consistent steam for

juicy baked items

More volume

More volume

thanks to rich

steam

Rich steam creates juicy baked goods

Rack oven ROTOTHERM Green with WP THERMOPACKAGE

Groundbreaking insulation = excellent savings

What do you do when you are cold? Of course, you wrap yourself up nice and warm from head to toe. That is just what we have done with the ROTOTHERM Green. What hat and coat are for people, WP THERMO PACKAGE is for ovens – an entirely new insulation concept. The full-surface insulation, the separated floor, the lowerable ramp and the steam proof door seal secured all around keeps the precious heat and the steam inside the oven and minimizes heat loss. ROTOTHERM Green thus saves on energy you would have to pay dearly otherwise.

Low floor heating

The floor only heats up to less

than 100 °C. The strain on

the floor in the bakehouse

therefore is considerably

less.

No condensation

build-up

on the floor means

improved value retention

of the oven.

High-tech insulation

Full-surface.

"Steam proof"

Lowerable ramp

and door seal all around,

thus reduced heat loss.

Full-surface insulation

The separated floor, the lowerable ramp and the steam proof door seal secured all around keeps the precious heat and the steam inside the oven and minimizes heat loss.

Fully automatic control of the rack oven

What makes the WP NAVIGO 3 software special

The automobiles of the future will navigate through traffic by themselves. For the ROTOTHERM Green the future has already begun with WP NAVIGO 3. The software is so intelligent that you can sit back, relax and hand over the steering wheel – or in other words: the fully automatic control of the oven.

Easy and intuitive

to operate

Imports existing recipes from

previously used baking

programs. Supports the

operating personnel with

WP ASSISTANT.

Easy-to-understand short

videos explain cleaning,

care and maintenance.

Partial loading

automatic

With WP ISOTHERMIC

BAKING.

High product

quality

Guarantees consistent high

quality baking results.

Optimizes burner

operating times

and thus reduces

energy costs.

Decentralised access

Grants access to authorized users

only via password assignment.

Networking

Can be linked via

WP BakeryControl (option)

a software for product

management.

WP NAVIGO 3 – fully automatic control of the oven

WP machines and equipment are easy to use, feature identical menu-assisted operation with uniform icons, colors, and procedures and provide powerful, secure remote diagnosis and maintenance, upon request.

WP INTELLIGENT ENERGY CONTROL (IEC)

The automatic energy saver

The start-stop system in the automobile turns the engine off independently when you are waiting at a red light. You can thus save on gas without even having to do anything. During a baking break, the intelligent software reduces the oven traget temperature. via a stand-by function. This automatically reduces your energy costs. The automatic start function heats back up to the required target temperature in time before the next baking process. And you're ready to go – just like when the traffic lights jump to green.

Baking at target

temperature

Unique finished

product thanks to

start of the baking

process at target

temperature.

Effective despite

baking breaks

No wasted energy

through by unnecessarily

continued heating of the

oven. Particularly effective

for businesses with

production-related

baking breaks.

Digital production management WP BAKERY CONTROL

Quality through transparency

The central software for your bakery, suitable for all WP baking ovens (plug & play installation), storage, display and export of oven, recipe and production data.

WP BAKERY CONTROL – the digital production management for monitoring, control, facilitated recipe entry and transparency

Networking ovens with WP BAKERY CONTROL: Control centre with beneficial automation for supervision, control and easier recipe entering.

WP VARIOPILOT

For every baked good the correct amount of recirculated air

You certainly drive slower in urban areas than on the freeway if you intend to arrive at your destination in an optimal manner. The WP VARIOPILOT is just as precautionary. It controls the amount of air in the baking chamber – perfectly adapted to the requirements of the respective end product.

Reduced amount

of recirculated

air

for softer baking

- Juicier baking items

- Shiny surface

Larger amount of air

for more powerful baking

- Faster heating

- Shorter baking time

- More crispness

- Better crust break

- More volume

Individually controllable amount of air

Its variable, finely adjustable setting options make the WP VARIOPILOT truly unique! This way you can bake an even wider assortment with best quality results.

The optimum energy-efficient heat recovery system for bakeries

Check & analysis – We will work with you to plan

Would you like to optimize your existing oven system or replace your outdated one? The WP RETHERM heat recovery system powered by Ganzenmüller can be can be newly planned or retrofitted to existing oven systems comprising ROTOTHERM rack ovens

WP RETHERM heat recovery powered by Ganzenmüller in action

The WP RETHERM heat recovery system powered by Ganzenmüller optimizes your oven system’s energy costs. The overall solution consists of smooth tube heat exchanger, control unit, storage tank, fresh air supply, flue and the connection to your heating and hot water installations.

What’s new?

Stay up to date with the WP BAKERYGROUP newsletter.

Subscribe to our newsletter

Do you want regular information about WP products and innovations?

Service and support

We make sure that your production lines run.

WP SERVICELINE

The WP SERVICELINE 24 is our guaranteed connection to the WP SERVICE and outside our opening hours to our emergency service:

Deutschland: +49 800 5 777 123

International: +49 1805 777 123

E-Mail: serviceline@@wpbakeryservice.de

Contact us

Any questions? We take care.

+49 9851 905-0

We have been developing ovens for bakers for over 140 years. Our knowledge of materials, technologies and construction creates long-lasting, economical and energy-saving rack ovens. Our experience and process expertise from dough preparation to baking give you insight into the entire production process. This allows us to develop ovens that fit perfectly into your production and open up new possibilities for you: Shorter baking processes and more uniform products for economically produced baked goods of the highest craftsmanship quality.

The ROTOTHERM Green rack oven sets new standards in your production: a baking process that is so perfect that it enables shorter baking times and even more uniform products.